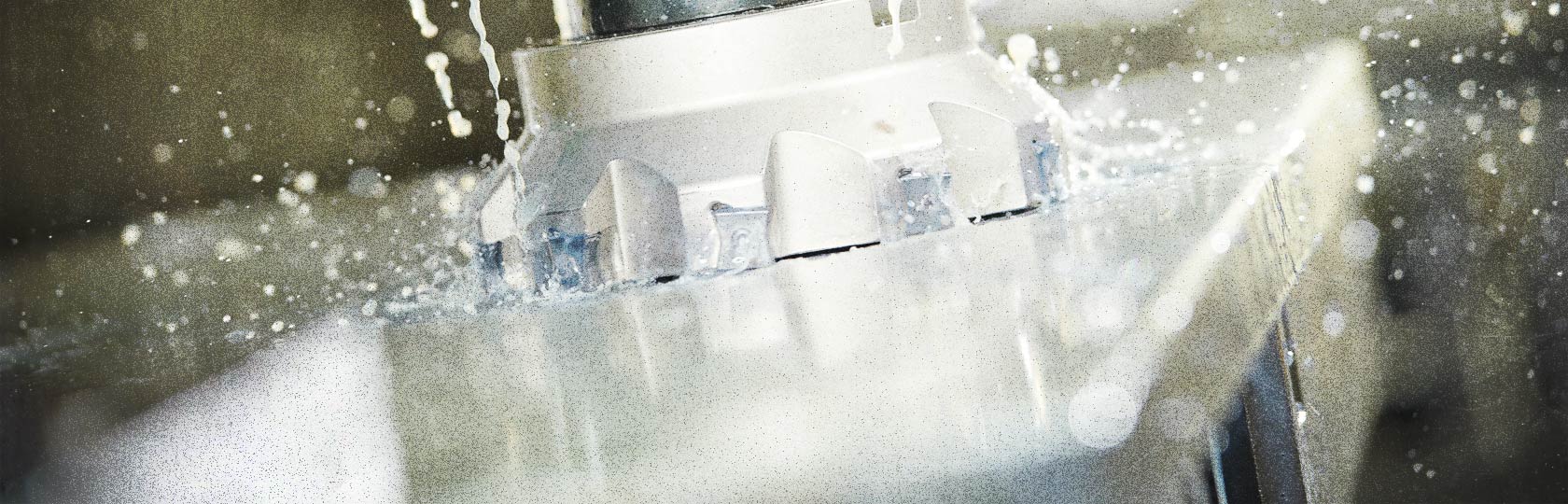

Wet-Abrasive Blasting is immersed in, and pressurized by water, then injected into regulated compressed airflow. The ability to adjust the blasting pressure as it discharges over a surface means wet abrasive blasting is a cost-effective and environmentally safe surface cleaning and preparation method, with a spark free and almost zero dust free environment.

The GEOBLASTER® wet blasting process eliminates more than 90% of the ambient dust, eliminates abrasive embedment in the substrate, and produces a more consistent finish. Wet Abrasive consumption is 1 /6th to 1/10th of the volume of traditional dry blasting methods, which makes it not only the safest and greenest option, but the most economical wet-blast option as well. With the elimination of dust, it also provides our employees a safer working area as most first aids are to the eye area.

GEOBLASTER® wet blast equipment will remove the toughest coatings, yet can be adjusted to clean the most fragile surfaces, without embedment or damage. Whether removing corrosion on a battleship or removing graffiti from sandstone, Wet-abrasive cleaning is extremely versatile.